The CIP system represents an automated cleaning technology that is prevalent in food production. It operates by circulating a cleaning solution through pipes, containers, and other production line equipment without the need for disassembly or relocation, thus guaranteeing hygiene and safety throughout the production process. Below is a comprehensive analysis of the CIP cleaning system from various perspectives.

Daily inspection and preparation

1. Power and gas source inspection:

Check if the power and gas sources are normal to ensure stable power and gas supply.

If there are any abnormalities, handle them promptly to avoid affecting the operation of the CIP system.

2. Acid alkali solution concentration check:

Regularly check the concentration of acidic and alkaline solutions to ensure compliance with cleaning requirements.

If the concentration does not match, it should be adjusted by using a pneumatic diaphragm pump to add concentrated solution or water.

Usually, the CIP system designed by VONFO company has online concentration monitoring to automatically adjust the concentration of acidic and alkaline solutions.

3. Cleaning time setting:

There are usually two ways to control the cleaning time. Firstly, the conductivity of the reflux cleaning solution is used to monitor the cleaning effect, automatically terminate the cleaning or extend the cleaning time. Secondly, the time relay is used to accurately set the cleaning time of each liquid to ensure the cleaning effect.

Operation and maintenance

1. Startup and cleaning:

According to the operating procedure, start the cleaning program for the water section, alkali section, and acid section in sequence.

During the cleaning process, pay attention to monitoring the opening and closing status of each valve and the flow and temperature of the cleaning solution.

2. Equipment cleaning:

After cleaning, rinse the inside of the equipment with RO water in a timely manner to avoid residual corrosion of the equipment. This is also within the setting program of the fully automatic CIP system.

Pay special attention to the cleaning and maintenance of centrifugal pumps, valves, and pipeline connections to prevent leaks.

3. Instrument inspection and calibration:

Regularly check the accuracy of each instrument and adjust the control point values according to process requirements.

Ensure that thermometers, level gauges, conductivity meters, and other instruments are working properly to improve cleaning accuracy.

Troubleshooting and Prevention

1. Leakage treatment:

When a leak is discovered, immediately stop the machine for inspection, identify the leak point, and replace the sealing ring or take other repair measures.

Regularly inspect pipeline connections and seals to ensure no leaks.

2. Monitoring of acid-base concentration:

Regularly monitor the reflux concentration of acidic and alkaline solutions, and make necessary acid and alkali supplements based on the test results.

Ensure stable concentration of acidic and alkaline solution to improve cleaning efficiency.

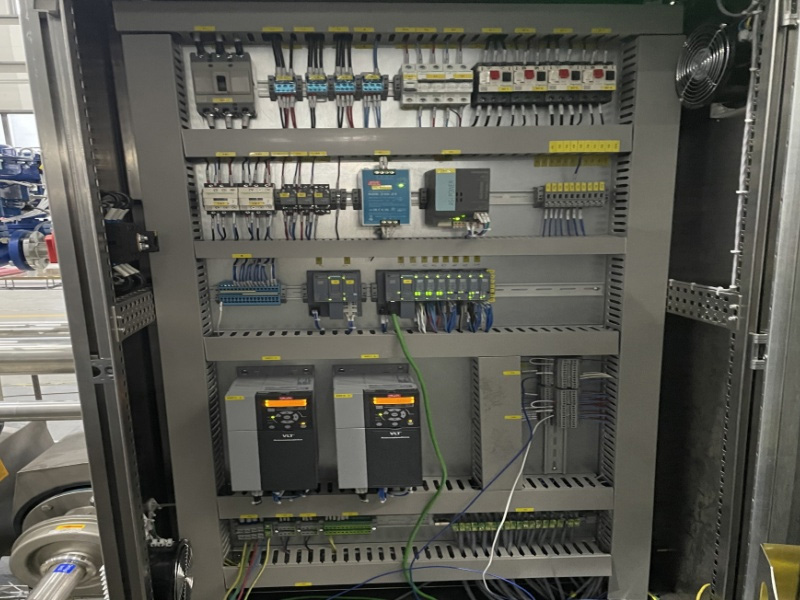

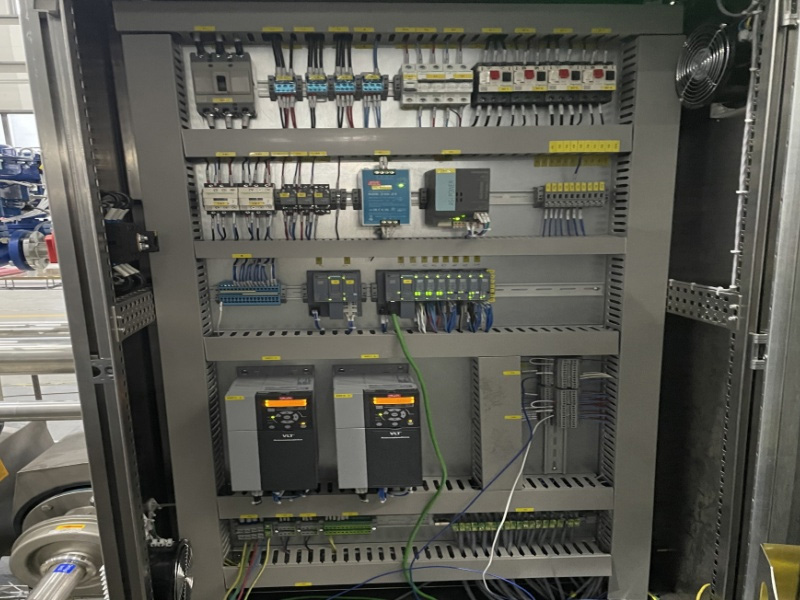

3. Electrical device inspection:

Regularly inspect electrical and control devices to ensure reliable grounding and prevent electrical faults.

Discover problems and repair them promptly to ensure the safe operation of the CIP system.

Regular maintenance and upkeep

1. Comprehensive cleaning:

Regularly conduct comprehensive cleaning of CIP systems, including equipment interiors, pipelines, valves, etc. VONFO company has designed reflux cleaning balls in the acid-base tank of CIP, which helps to effectively clean the interior of the CIP system.

Thoroughly clean and disinfect equipment and pipelines using efficient disinfectants.

2. Equipment maintenance:

Regularly inspect the wear and tear of equipment components and replace vulnerable parts in a timely manner.

Keep the equipment clean and dry to prevent corrosion.

3. Records and Reports:

Establish a comprehensive record and reporting system to document the cleanliness and maintenance of the CIP system.

Regularly analyze and evaluate records to provide a basis for subsequent maintenance and upkeep.

Training and Staff Management

1. Professional training:

Provide professional CIP system operation and maintenance training for production personnel.

Improve employees' awareness and skill level in operating and maintaining the CIP system.

2. Operating procedures:

Establish strict operating procedures and management systems to ensure that employees operate in accordance with the procedures.

Strengthen supervision and assessment of employees to ensure effective implementation of various measures.

In summary, the complete maintenance guide for CIP system covers multiple aspects such as daily inspection and preparation, operation and maintenance steps, troubleshooting and prevention, regular maintenance and upkeep, training and personnel management. Only by strictly following the guidelines for operation and maintenance can the normal operation of the CIP system be ensured and its service life be extended.