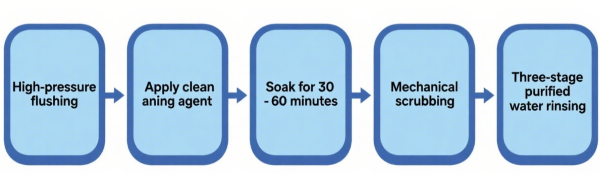

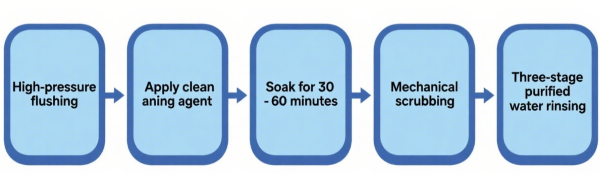

Standardized cleaning process

Step 1: Pre-treatmentEmpty the medium → pre-flush with high-pressure water gun (≥ 50Bar) → remove the surface residue

Preparation tools: food-grade soft brush, non-woven cloth, and pH test paper

Step 2: Detergent selection

Residue Type Cleaner Mechanism

Grease/Organic Alkaline Cleaner (pH 10-12) Saponification Decomposition Organic Residue

Scale/Mineral Acid Cleaner (pH 2-4) Dissolves Calcium and Magnesium Deposits

Brewing detergent for hops/yeast Enzyme hydrolysis biomembrane

Step 3: five-steps cleaning method

Key control points:

Flushing water quality: conductivity ≤ 5 μ S/cm (secondary pollution prevention)

Drying method: sterile compressed air purging+65 ℃ hot air drying

Step 4: Cleaning Verification

Visual inspection: no visible residue on the inner wall, bright welds, and no pitting

White cloth test: wipe the inner wall without stain

Physicochemical test: pH value/conductivity meet process water standard

Microbial sampling inspection (required for pharmaceutical/food): total number of colony ≤ 10CFU/100mL