Description:

Carbonated drinks also called CSD drinks,it is composed of water, sweeteners, flavors,colors, carbon dioxide and other ingredients.

Carbonated drink production line is mainly applicable to sparking water, carbonated soft drink, soda water, carbonated juice, etc. The filling temperature is 0-5 degree.

The carbonated drinks production line is composed of RO water treatment system, sugar and ingredient dissolving system, carbon dioxide and syrup premixing system, filling and packing system and CIP system.

Carbonated Drink Production Line End Product and Package:

Carbonated water (Sparking water): The main ingredients are pure water, syrup and carbon dioxide.The beverage can be filled into PET or glass bottles, Aluminum cans.

Fruity flavor carbonated drinks: it is composed of water, syrup,flavor, sweetener and C02.All these ingredients fully mixed and filled into bottles or cans.

Juice carbonated drinks: This type of beverage consists of concentrated fruit juice, drinking water and C02.When production this type of beverage, the juice beverage needs to be sterilized after the juice is mixed with water, then the pasteurized juice can be mixed with carbon dioxide and filling into bottles or cans.

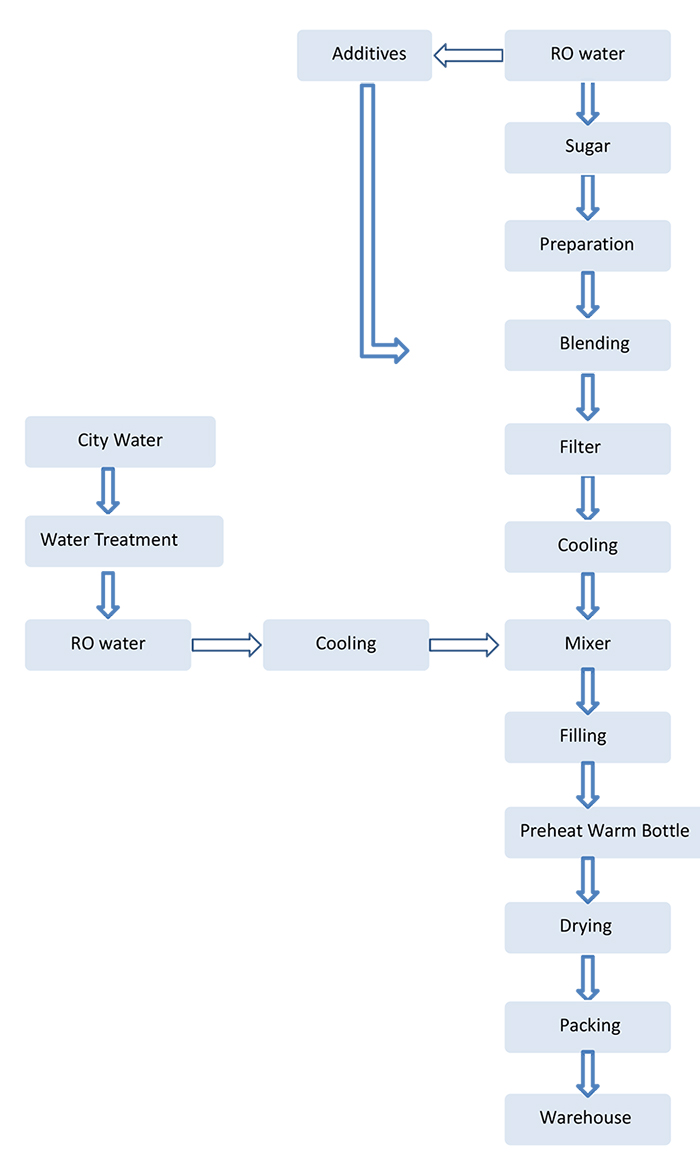

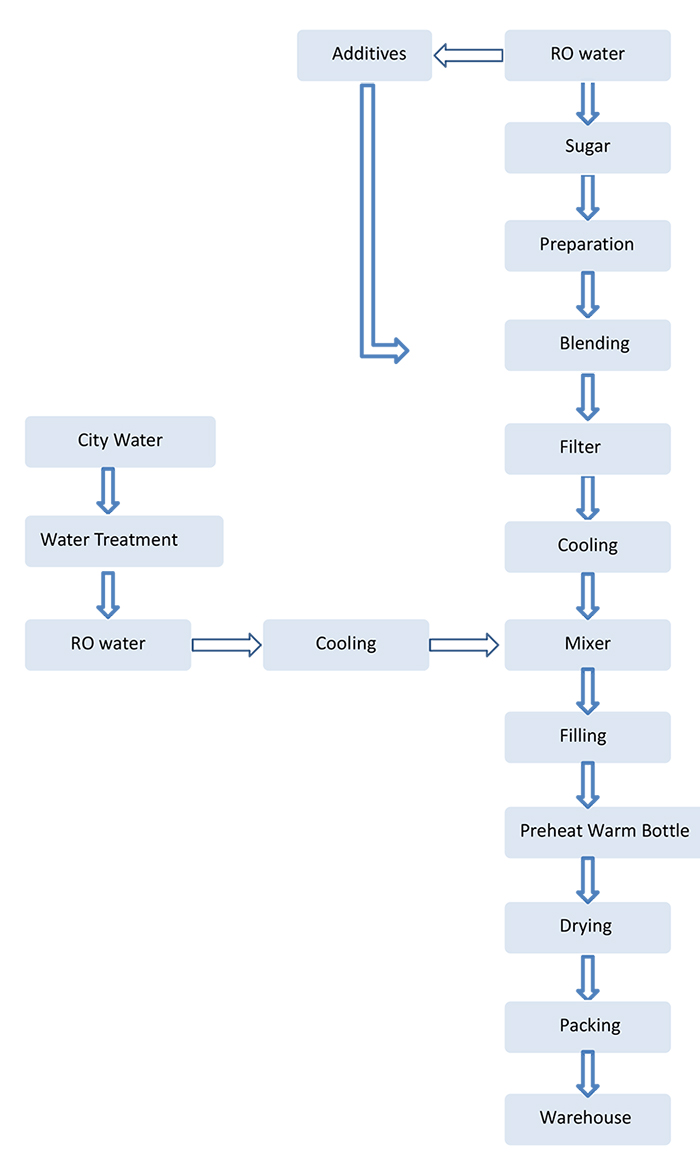

Process Flow:

Main Features:

1 | Raw materials | Pure water, CO2,sugar, additive,etc |

2 | End products | sparking water, carbonated soft drink, carbonated water, carbonated juice |

3 | Processing capacity | 1000-20,000L/h |

4 | Terminal package | Plastic bottle, glass bottle.can, etc |

5 | Production control automation | Semi-automatic /Fully -automatic control |

6 | We can design it according to client’s special requirements. |

Complete ice cream Production Line equipment:

1. sugar dissolving system

2. Preparation and mixing system

3. CO2 Treatment System

4. Carbonated Drinks Mixing system

5. Carbonated Drinks Filling & Packaging system

6. CIP system

7. Water Treatment system

8. Ice water system

9. Compressed air system

10. Steam Boiler