Description:

Milk-containing beverages refer to products made from fresh milk or dairy products through fermentation or non-fermentation. Milk-containing beverages are divided into formulated milk-containing beverages and fermented milk-containing beverages. Formulated milk-containing beverages are beverages prepared by adding one or more of water, white sugar, sweetener, sour agent, fruit juice, tea, coffee, plant extracts, etc., using milk or dairy products as raw materials.

The capacity of the milk beverage processing line is available for customers to choose from 1T/H-20T/H. and the final product can be packed into cartons, plastic bottles or glass bottles.

The entire production line is equipped with a CIP cleaning system to clean equipment, pipelines and storage tanks to ensure the sanitary conditions of the production line thereby producing high-quality products.

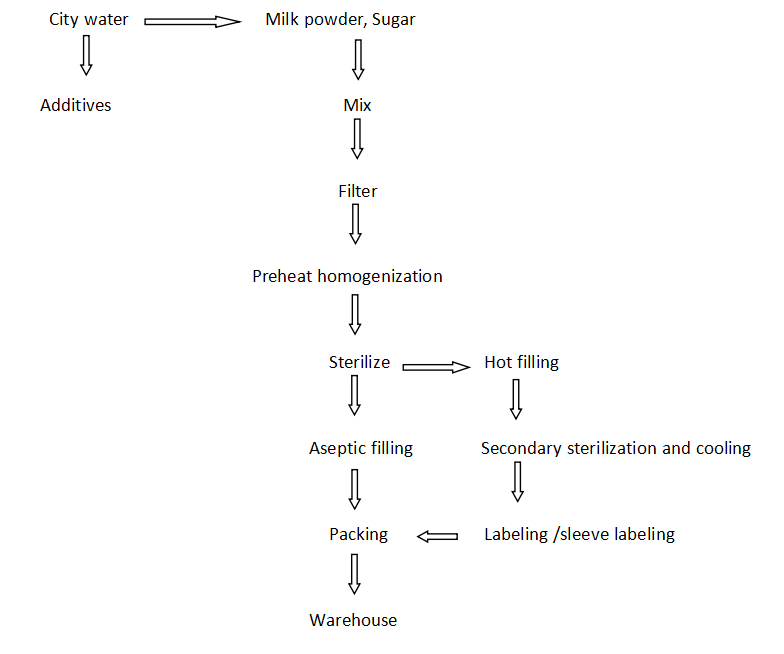

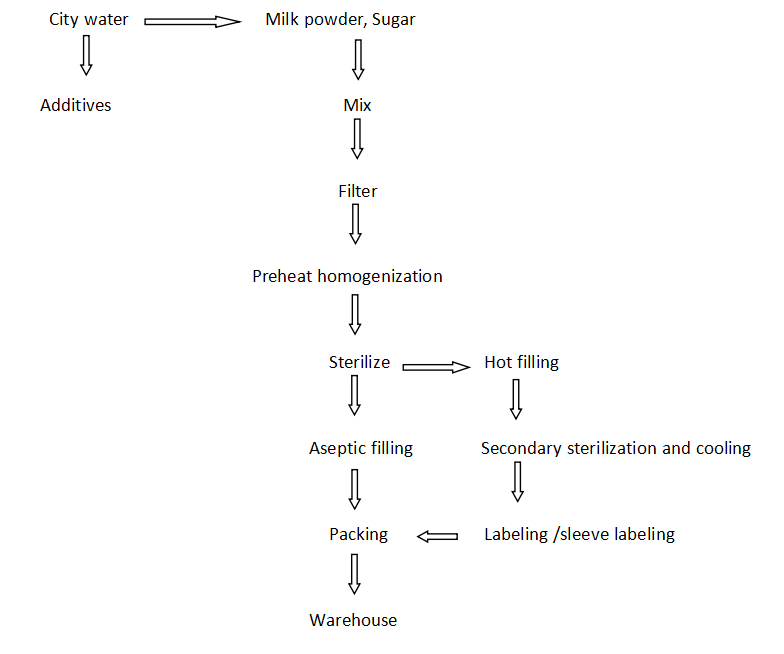

Process Flow:

Main Features:

1 | Raw materials | Fresh milk/milk powder,juice,,RO water, additive etc. |

2 | End products | Flavored milk beverage,Fermented milk beverage |

3 | Processing capacity | 1000-20,000L/h |

4 | Terminal package | plastic bag, plastic bottle, glass bottle, can etc. |

5 | Production control automation | Semi-automatic /Fully -automatic control |

6 | We can design it according to client’s special requirements. |

Complete ice cream Production Line equipment:

1. Milk powder/additive/Sugar dissolving system

2. Preparation and mixing system

3. Sterilization and homogenization System

4. Milk beverage Filling & Packaging system

5. CIP system

6. Water Treatment system

7. Ice water system

8. Compressed air system

9. Steam Boiler