Description:

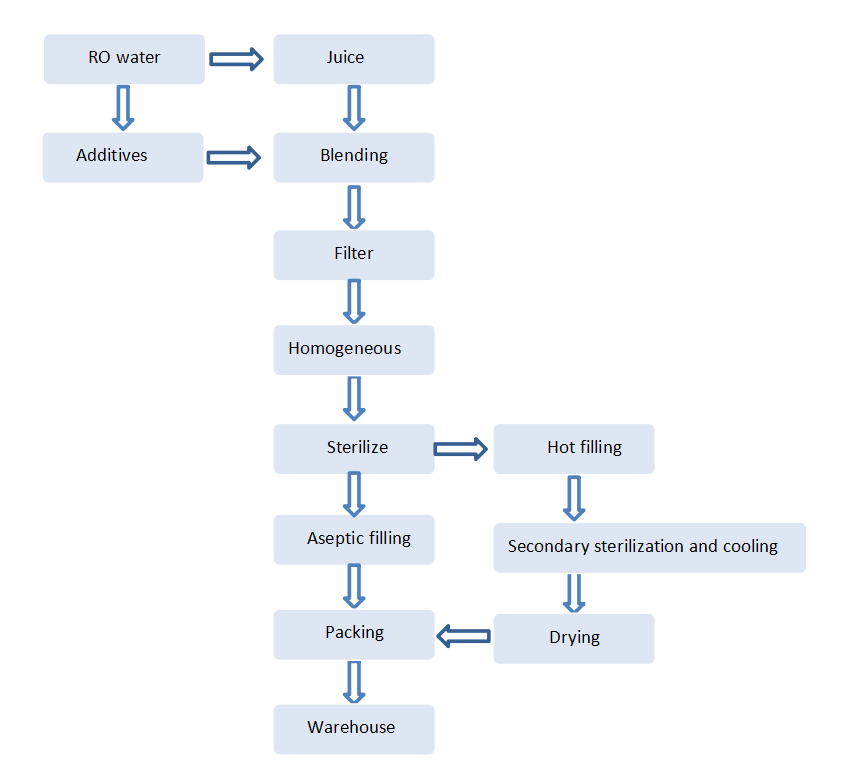

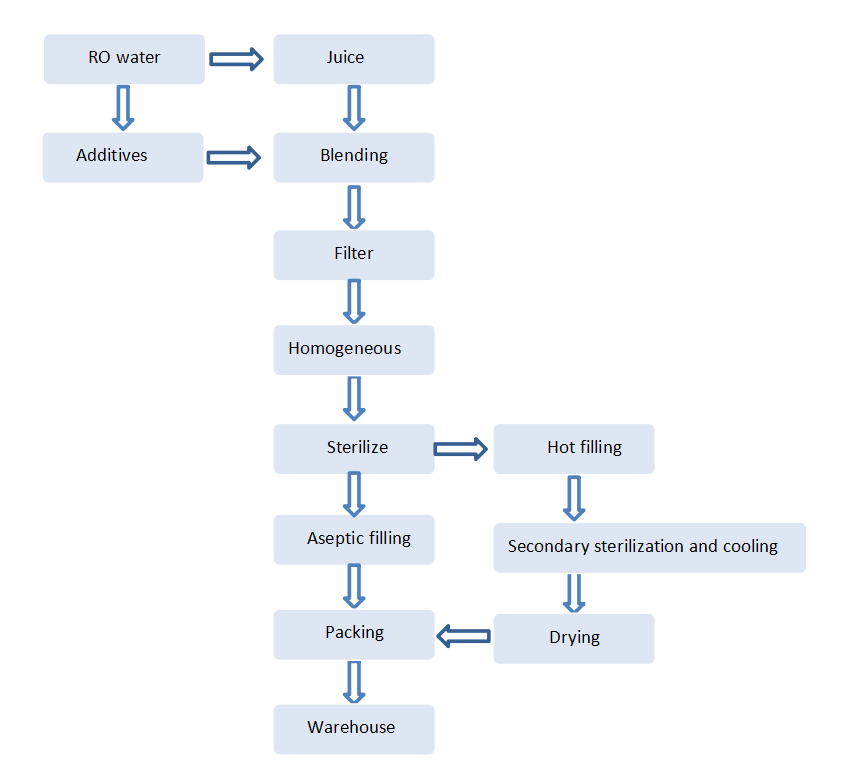

The juice beverage production line taken various fresh fruit, juice concentrate, juice powder as main raw material, through washing, extraction, cooking, pulping, homogenization, degassing, sterilization and filling etc flow procedures, which can be manufactured into various fruit juice, flavor juice beverage.

High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in various juice making machines.

PLC control the whole fresh fruit juice manufacturing plant, saving labor force and facilitate production management.

Full-auto CIP cleaning, to ensure whole fruit juice processing line equipment meet food sanitary safety requirements.

Process Flow:

Main Features:

1 | Raw materials | Various fruit juice, concentrated juice, juice powder,RO water, additive |

2 | End products | Fruit juice ,juice beverage |

3 | Processing capacity | 1000-20,000L/h |

4 | Terminal package | plastic bag, Plastic cup, plastic bottle, glass bottle, can etc. |

5 | Production control automation | Semi-automatic /Fully -automatic control |

6 | We can design it according to client’s special requirements. |

Complete ice cream Production Line equipment:

1. Juice powder/additive/Sugar dissolving system

2. Preparation and mixing system

3. Sterilization and homogenization System

4. Juice beverage Filling & Packaging system

5. CIP system

6. Water Treatment system

7. Ice water system

8. Compressed air system

9. Steam Boiler