Description:

Condensed milk is made between two different types; unsweetened and sweetened condensed milk. Both products can be made from fresh milk or milk powder.

Unsweetened condensed milk (also called evaporated milk) is a sterilized product, light in colour and with the appearance of cream.

Unsweetened condensed milk, is normally packed in cans,which are then sterilized in autoclaves

Sweetened condensed milk is basically concentrated milk, to which sugar has been added.

The product is yellowish in colour and high viscous.The high sugar concentration in sweetened condensed milk increases the osmotic pressure to such a level that most of the microorganisms are destroyed.

This product is not heat treated after packaging as its high sugar content preserves it for a long shelf-life. The sugar concentration in the water phase must not be less than 62.5 % or more than 64.5 %. At the latter level, the sugar solution reaches its saturation point and some sugar may then crystallize, forming a sediment.

Condensed milk production line includes all the necessary units, from the acceptance of raw materials to the heat treatment of the finished product before packaging. We provide various technologies for the production of condensed milk. The lines are equipped with an automatic control system that is easy and convenient to use.

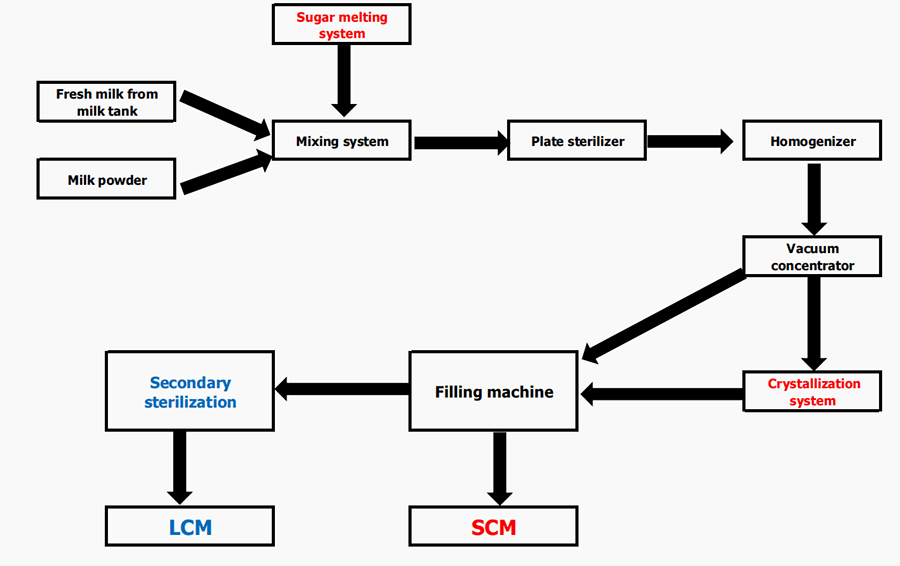

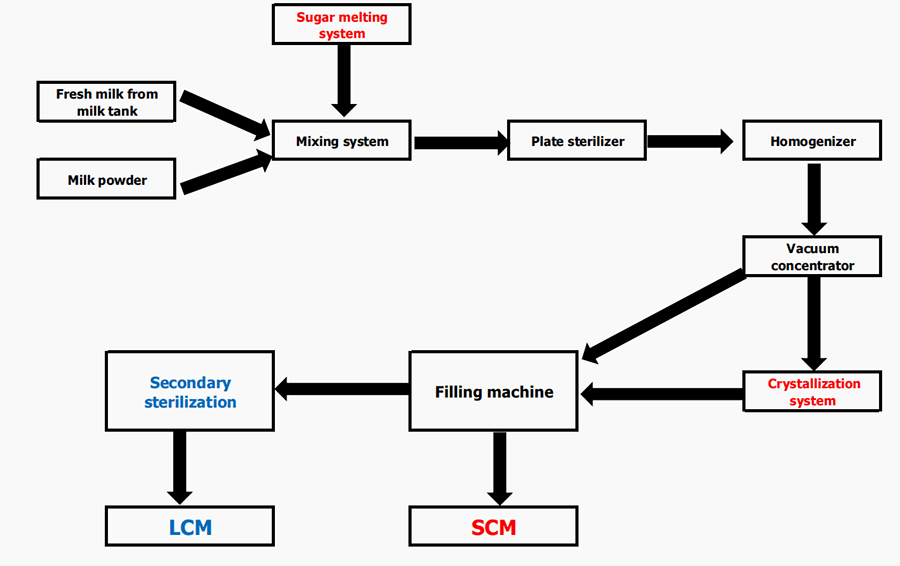

Process Flow: LCM

Main Features:

1 | Raw materials | Fresh raw milk /milk powder |

2 | End products | Unsweetened condensed milk/Sweetened condensed milk |

3 | Processing capacity | 300-2500KG/h |

4 | Terminal package | Tin can, glass bottle,glass Drum etc |

5 | Production control automation | Semi-automatic /Fully -automatic control |

6 | We can design it according to client’s special requirements. |

Complete condensed milk Production Line equipment:

1. Raw milk storage system/milk powder and sugar dissolving system

2. Homogenization and pasteurization Section

3. Concentration system

4. crystallization system

5. Filling system

6. Secondary sterilization system

7. CIP system

8. Water Treatment system

9. Ice water system

10. Compressed air system

11. Steam Boiler