Description:

UHT milk is a dairy product with a long shelf life that can be directly consumed.

This dairy product not only improves the color and taste, but also improves the original nutritional value.

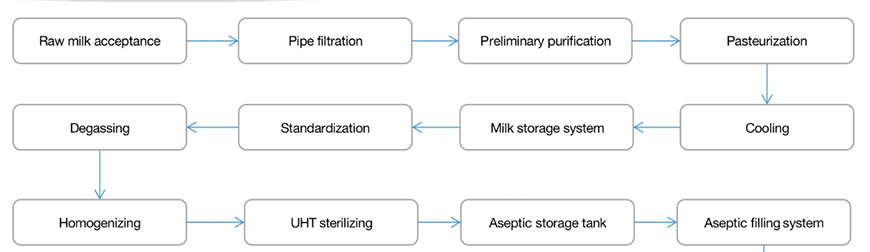

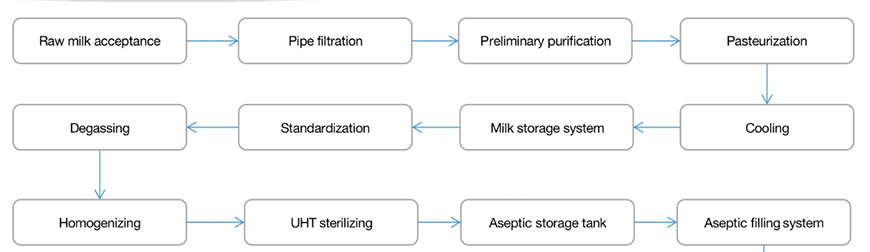

Sterilized milk, also known as long-lasting milk, refers to products that are using fresh milk or milk powder as raw material. then after purified, standardized, homogenized, UHT sterilized and aseptically packed into containers.

UHT milk does not need to be refrigerated and can be stored at room temperature. Depending on the packaging container, the shelf life generally ranges from 3 months to 12 months.

The entire UHT milk processing line keeps materials processed in a closed environment to ensure the commercial aseptic state of the final product.

The capacity of the production line can be designed from 1 ton/hour to 50 tons /hour according to the different requirements of customers

200ML--2500ML aseptic cartons, aseptic pouches or PE bottles can be packed according to client's different requirements.

The auxiliary equipment like CIP system, chi water generating system, boiler, RO soft water treatment system are needed for the whole production line.

Process Flow:

Main Features:

1 | Raw materials | Fresh raw milk/Milk powder |

2 | End products | UHT milk |

3 | Processing capacity | 1000-20000L/h |

4 | Terminal package | Aseptic Carton (like Tetra Pack), Aseptic Pouch, etc. |

5 | Production control automation | Fully -automatic control |

6 | We can design it according to client’s special requirements. |

Complete UHT Milk Production Line equipment:

1. Raw milk storage or milk Powder Dissolving system

2. Homogenization and UHT sterilization Section

3. Aseptic Filling & Packaging system

4. CIP system

5. Water Treatment system

6. Ice water system

7. Compressed air system

8. Steam Boiler