Description:

Powder milk is made from cow milk, goat milk and other mammal's milk as raw material, processed by sterilization, cream separation (depends on what kind of milk required), concentration and dry into powder, which is portable and preservative

Milk powder production process is to make the liquid milk into powdered solid, which aroma, flavor retention and important nutrients, such as protein, fat, carbohydrates, vitamins, minerals and so need to try to retain.

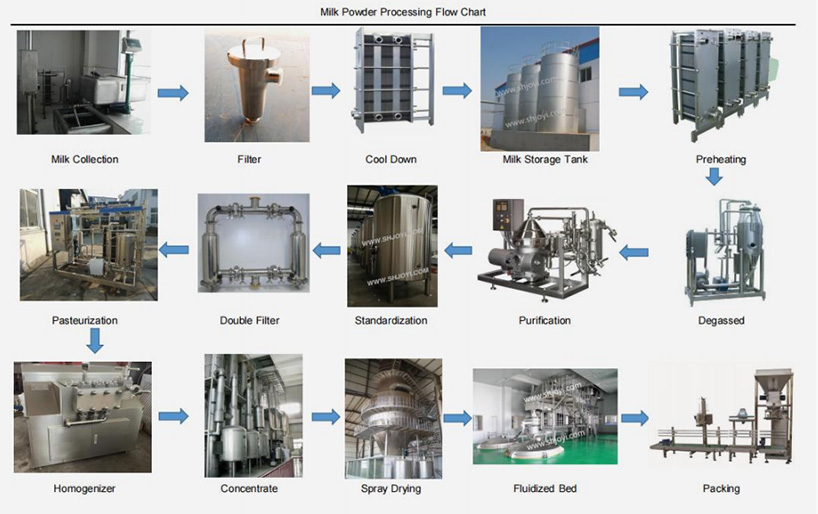

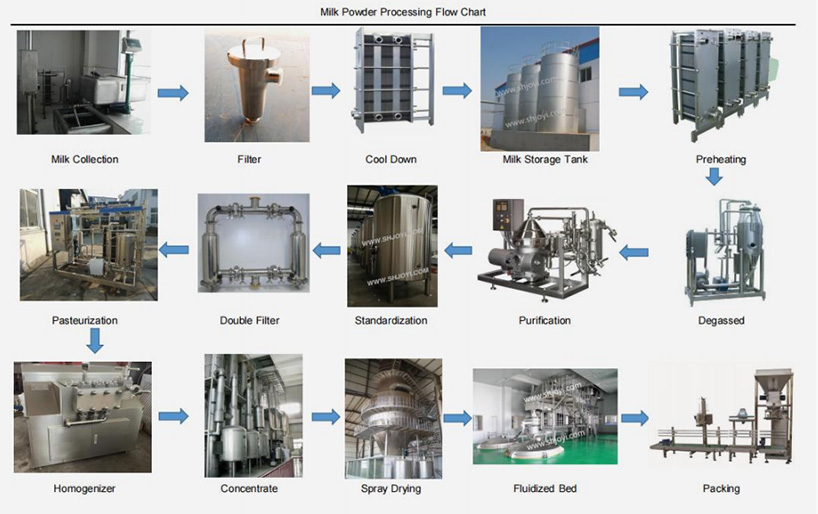

Process Flow:

Main Features:

1 | Raw materials | Fresh raw milk |

2 | End products | Milk powder |

3 | Processing capacity | 300-5000L/h |

4 | Terminal package | Cans, plastic bag, etc |

5 | Production control automation | Semi-automatic /Fully -automatic control |

6 | We can design it according to client’s special requirements. |

Complete Milk powder Production Line equipment:

1. Raw milk storage system

2. Homogenization and pasteurization Section

3. Concentration system

4. Drying system

5. Milk Powder Packaging system

6. CIP system

7. Water Treatment system

8. Ice water system

9. Compressed air system

10. Steam Boiler